Double-head high power standard series pedal/Pneumatic

FEATURE

SYNCHRONOUS CUTOFF OF OIL PRESSURE AND HIGH FREQUENCY

This unit uses the combined mould with blade or ally steel blade to directly cut the voltage material at the blade position of the mould through the oil pressure system, following the completion of the high frequency voltage program. Thus, it can reduce the rejected products caused by cutter's additional cut-off after the high frequency, and greatly improve the production efficiency. This machine is most applicable for cutting and processing the voltage of high accuracy trademarks, vamps and watchbands.

JAMMING PREVENTION DEVICE

Equipped with frequency stabillizer and high frequency magnetic leakage suppressor. This device prevents leakage of electromagnetic radiation to avoid jamming other electrical instruments such as televisions and radios, etc.

EASILY ADJUSTABLE TUNER

Output ower can be adjusted at the tuner according to electrode size and material thickness. In addition, other control devices and special electrial circuits have cut down required welding tie consderably to raise the machine productivity.

HIGH SENSITIVITY SAFETY PROTECTION CIRCUIT

If the current load exceeds the limit during operation, the overload current relay will cut off the high voltage automatically so as to protect the oscillating tube and rectifier. It is also provided with high sensitivity spark arrester, to provide dual protection and minimize the damage of electrode and materials.

APPLICATION RANGE

High-frequency processing of high precision shoes, trademarks, portfolios, hang bags, stationary and nameplates, etc.

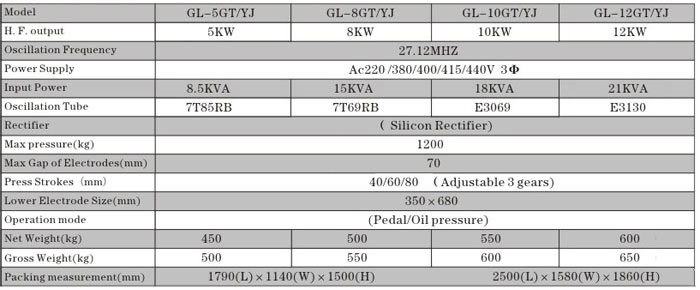

SPECIFICATIONS

The manufacturer reserves the right to modify the design,specificationgs mehanismes etc,without notice.

Samples photos